Ever since we launched Montana Knife Company, buyers have asked us why we coat our blades and whether coating a blade really helps with durability.

Is it truly necessary? Can the coating be redone? Is it food safe?

Today, we’ll answer these questions once and for all, explain our process, and compare the pros and cons of Parkerizing vs. Cerakote.

Parkerizing vs. Cerakote: What Is Parkerizing?

Before we can compare Parkerizing vs. Cerakote, let’s define each process.

Parkerizing, or phosphate conversion coating, is a chemical treatment that protects a steel surface from corroding through oxidation. Parkerizing can only be performed on mild or carbon steel, so stainless, aluminum, and titanium blades are a no-go.

Simply put, Parkerizing pre-rusts the blade before rust has a chance to take over. Rust happens, but with Parkerizing, we can beat it to the punch and guide the process on our terms.

How Parkerizing Is Performed

A critical first step in Parkerizing is to prep the surface. When it comes to coating a blade, cleanliness is key, and we blast all our blades to ensure an even finish. Any grease, oil, or fingerprints will disrupt the process.

Next, we create a chemical solution, called a bluing bath, of manganese or phosphate magnesium. That mixture is heated to just under 200 degrees, and the blades are placed in the solution.

As the chemicals react with the steel, the solution comes to a frothy, hard boil, which lasts about five minutes. Throughout the next seven or eight minutes, the boiling subsides until it stops altogether. At that point, the blades are fully Parkerized.

To the naked eye, it’s as simple as that. But it’s far more interesting at a chemical level, where the solution is in fact attacking and oxidizing the surface of the steel.

The blades, now sporting a black or dark gray finish, are removed from the solution and placed in clean, flowing water. This step neutralizes the solution and removes residue. The final step is to put the blades in water-displacing oil. After about 24 hours, the coating has fully cured and become rust-resistant.

Advantages and Disadvantages of Parkerizing

Oxygen contact is what causes steel to rust, which is hard to avoid here on planet Earth. A Parkerized chemical coating ensures oxygen can no longer touch the steel — easily the greatest advantage of Parkerizing.

Most people are familiar with Parkerizing in the context of military equipment — steel products that must be protected from rust in harsh conditions. Parkerizing also eliminates shine, a great advantage on the battlefield. You wouldn’t want to be holding a shiny rifle that reflects light into the watchful eye of a sniper. Old guns, too, are very durable and hold up for decades due to Parkerizing.

Of course, there’s no such thing as a scratch- or wear-proof coating, but Parkerizing is one of the most durable coatings out there. It’s not a paint that chips, thickens a blade, or scratches off easily.

Once you’ve neutralized and cleaned the blade, Parkerizing is also food safe. It’s no different than the patina on an old butcher knife. There isn’t any sort of chemical or foreign substance that can come off in your food.

But there are drawbacks to any coating. Parkerizing can wear down over time, and it’s difficult to redo the Parkerizing process without dismantling the entire knife. It’s also highly likely to wear unevenly. Finally, you don’t get many color options — a Parkerized blade comes out either black or dark gray.

Parkerizing vs. Cerakote: What Is Cerakote?

Now let’s look at the other side of Parkerizing vs. Cerakote.

Cerakote is a form of paint, meant for coating the blade, that’s baked onto the surface of the steel. Like any paint, Cerakote doesn’t adhere well to an extremely polished or slick surface. The surface of the steel has to be roughed up through bead blasting or sandblasting to give the Cerakote something to bite onto and hold.

Cerakote is sprayed on in a spray booth. The coated blades are then hung in an oven and baked at 300–350 degrees. Generally, MKC knife blades are baked closer to 300 degrees so as not to affect the heat treat of the steel.

Advantages and Disadvantages of Cerakote

Cerakote is quite durable compared to other coatings, and because it isn’t a chemical process, it can be added to just about anything that can be baked, including stainless steel.

Cerakote also opens up all kinds of aesthetic opportunities. Unlike in Parkerizing, virtually any color is available. You can actually laser patterns or even names into the steel using stencils and then re-Cerakote it. The only limit is your imagination.

One disadvantage of Cerakote is that, while it helps protect against rust, it’s not rustproof — no coating is. When we sharpen our blades or laser our logo, we expose the steel to oxygen, creating a place where rust can start.

Another disadvantage is that Cerakote wears less gracefully than Parkerizing. In my opinion, Parkerized blades develop character over time.

Cerakote is technically food safe, but I consider Cerakote food safe the same way nonstick pans are food safe. After a few years, the nonstick surface has totally chipped away, and you wonder how much of it you’ve eaten.

That said, most of the damage to Cerakote occurs when the blade is banging around in a dishwasher or drawer, not when cutting food. With proper care, Cerakote will hold up well over time.

Parkerizing vs. Cerakote: Which Is Best for You?

Still can’t decide between Parkerizing vs. Cerakote? Ask yourself the following questions.

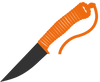

How much does color matter to you? Parkerized blades only come in two colors (black and dark gray) while Cerakote allows for more customization. MKC only offers Parkerizing in black, and only on carbon steel blades. If you want a knife in a different color, like our blaze orange, you’ll have to go for a knife made with stainless steel. Generally, all black MKC blades are Parkerized except in the case of our chef’s knives, which are black Cerakote.

What does your environment look like? Your answer will determine what kind of blade is necessary to get your job done — carbon steel or stainless steel? Remember, you can’t Parkerize stainless steel.

One thing I can assure you of is that both Parkerizing and Cerakote hold up extremely well. I’ve done the testing myself — chopping 2x4s — to find out for sure.

by Josh Smith, Master Bladesmith and Founder of Montana Knife Company