Walk onto any job site where linemen are working. You’ll see Klein knives hanging from tool belts, bouncing against legs, and getting caught on equipment.

These knives fall off bucket trucks daily. They chip when you look at them wrong. The 440A steel loses its edge before lunch. And when they disappear or break, you buy another one.

Losing or replacing a $30 knife every month runs you $360 a year. Over a 20-year career, you’re looking at $7,200 spent on disposable knives that never performed well in the first place.

But the real cost is the extra effort you put into every cut with a dull blade. It’s the fatigue in your forearms at the end of a shift, the close calls when a dull knife slips because you had to force it through tough sheathing.

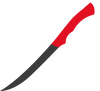

The Great Falls Skinner changes that equation. Named after Great Falls, Montana, which you may have heard dubbed “the Electric City” for its hydroelectric dams, this one knife, built right and insured for life, replaces a career’s worth of disposable tools.

Why I Built a Better Wire-Skinning Knife

Before founding Montana Knife Company, I spent 10 years as a lineman.

Our wire-skinning knives arrived from the factory already dull. The edges were so poor that guys were putting three times the effort into every cut, fighting through rubber and plastic sheathing with blades that belonged in a scrap bin.

So I started sharpening my crew’s knives. At first, they complained. “Josh, this is too sharp. It’s dangerous.”

But after a week of using properly sharpened blades, my crew realized how much energy they’d been wasting. Cutting through wire sheathing became effortless. What used to take muscle now took technique.

That experience informed the Great Falls Skinner: the first premium wire-skinning knife for professionals who refuse to treat their tools as disposable.

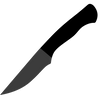

Refined Geometry From 10 Years of Field Experience

Standard wire-skinning knives have an aggressive hook that looks impressive but fights you during actual use.

The hook is too severe, making it harder to control. The tip is too blunt for precision work. And the knife’s geometry fights against the natural motion of stripping wire.

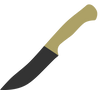

The Great Falls Skinner features a more gradual curve with a pointier tip. This refined hawkbill shape lets you whip the blade around wire and slide sheathing off in one smooth motion. At 0.100″ thick, the Great Falls Skinner maintains the proven thickness professionals expect, but the improved geometry means you get better results with less effort.

Watch a lineman work with a properly designed wire-skinning knife, and you’ll see the difference. There’s no forcing or sawing back and forth. Just clean, efficient cuts that let you focus on the job instead of fighting your tools.

MagnaCut Steel: Because Your Knife Should Work as Hard as You Do

While other manufacturers save pennies with soft 440A steel, we chose MagnaCut stainless steel for the Great Falls Skinner.

MagnaCut stays sharp through an entire shift of cutting rubber and plastic sheathing. When it finally needs touching up after weeks of hard use, it sharpens easily. The Great Falls Skinner doesn’t demand special equipment. Just a few passes on a stone and you’re back to work.

The corrosion resistance matters, too. Linemen work in all kinds of weather, dealing with moisture, chemicals, and environmental exposure that would destroy lesser steels. MagnaCut laughs at these conditions and maintains its integrity year after year.

Built for Gloved Hands and Real Work

The Great Falls Skinner’s squared G10 handle was designed for the reality of line work. When you’re wearing thick rubber gloves and working with high voltage, you need positive grip and zero rotation.

The squared profile prevents the knife from twisting in your hand, and the handle is intentionally oversized to accommodate lineman’s gloves, because we know you don’t take them off to use your knife.

That massive forward guard isn’t decorative. It keeps your hand where it belongs, especially when you’re working fast or in awkward positions. During electrical work, one slip can lead to more than a cut finger.

The Shotgun Ring That Actually Works

The rear ring on the Great Falls Skinner connects to hot sticks (shotgun tools) for safely cutting wire sheathing from a distance.

We tested this connection extensively with actual shotgun sticks to make certain it locks in securely. No play, no wobble, just solid engagement when you need to work remotely on energized equipment.

When you’re not using it with a hot stick, that same ring acts as a hanging point. Hook it to your belt, your bucket, or a carabiner. Some guys run a thick cord through it with a bead so they can retrieve it easily from deep pockets.

The Scraping Notch: Small Detail, Big Difference

See that notch on the blade’s spine? That’s for scraping corrosion off copper wire.

Clean connections matter in electrical work. A corroded connection means resistance, heat, and potential failure. The dedicated scraping notch lets you clean wire quickly without dulling your primary edge.

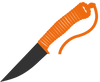

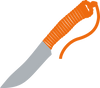

American-Made Kydex Sheath in Two Strategic Colors

Each Great Falls Skinner comes with a custom Kydex sheath, featuring a loop that attaches the knife to tool belts or carabiners.

We offer it in black for those who prefer traditional gear, but we strongly recommend the high-vis orange. After watching too many knives disappear off bucket trucks, we made a sheath you can spot from across a job site.

A note on safety: While many linemen prefer to keep their knife hanging unsheathed during active use for quick access, a sheathed blade prevents accidental cuts when climbing, reaching through tight spaces, or bumping into coworkers on crowded job sites.

The Great Falls Skinner’s refined point and sharp edge can catch on clothing or equipment when hanging loose. The sheath’s retention system holds securely while allowing quick deployment.

The MKC Generations® Promise: Free Maintenance for Your Entire Career

Every Great Falls Skinner is insured by our MKC Generations® promise.

We’ll clean, sharpen, repair, and reshape your blade when necessary, free of charge. Send it to us covered in a year’s worth of job site abuse, and we’ll return it ready for another year of hard work.

Those wear marks from daily use will stay right where they belong. They tell the story of lights kept on and communities powered.

Unlike the knife manufacturers who expect you to throw away and replace their products, we’ll keep your Great Falls Skinner in service for your entire career and beyond. Pass it down to the next generation of linemen. We’ll keep it working for them, too.

For the Linemen Who Keep America Running

The Great Falls Skinner isn’t trying to win any beauty contests. Every inch was designed for function, informed by decades of field experience and built to the standards professionals deserve.

This knife is for the linemen who restore power after storms, maintain the infrastructure we all depend on, and work in brutal conditions to keep the lights on. The knife industry has underserved you for too long, forcing you to choose between disposable junk and expensive tactical knives that miss the mark.

The Great Falls Skinner is different. It’s a professional tool for professional linemen, built by someone who’s been there and decided to do better.

by Josh Smith, Master Bladesmith and Founder of Montana Knife Company